- البريد الإلكتروني: info@cnlcdisplay.com

- الهاتف: 8618688410533

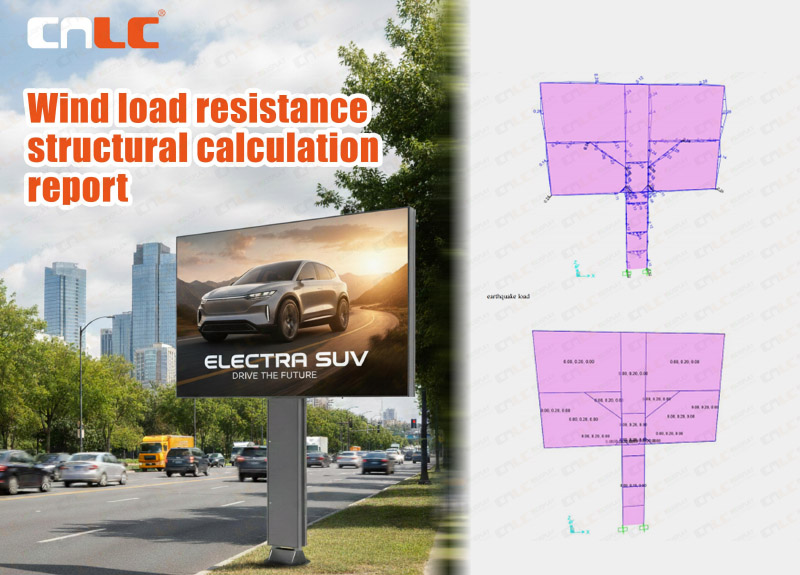

كيف تضمن حسابات أحمال الرياح الهيكلية السلامة طويلة الأمد للوحات الإعلانية الخارجية بتقنية LED

كيف تضمن حسابات أحمال الرياح الهيكلية السلامة طويلة الأمد للوحات الإعلانية الخارجية بتقنية LED

تل : 8618688410533

تل : 8618688410533 تل : 8602082332833

تل : 8602082332833 البريد الإلكتروني : info@cnlcdisplay.com

البريد الإلكتروني : info@cnlcdisplay.com ابق على اتصال احصل على أخبارنا وعروضنا والمزيد...

ابق على اتصال احصل على أخبارنا وعروضنا والمزيد...